|

Ducati 999R 05 Homolagation Superbike

July

8th 2004 - An evolution of power, aerodynamics and style,

for a dream Ducati which is more competitive and powerful than

ever. Based on the motorcycle representing Ducati in this year's

American Superbike Championship (AMA), the 999R has been significantly

upgraded for the American market.

A new front fairing, new rear swing arm and suspension, a major

upgrade to 150 horsepower for the engine are all intended to reinforce

the bike's Superbike status.

AMA technical

regulations allow fewer modifications to the engine than the international

Superbike regulations so Ducati, which returned to the AMA championship

this year, has produced an engine with technical characteristics

that are much closer to those of the racing version. The new 999R

is yet another step forward in Ducati tradition, which has always

been characterised by the manufacture of series production bikes

similar to their race versions not only in styling, but also in

technical features.

Previous

editions of the R model Ducati Suberbikes were produced in limited

500 bike production runs each season to homologate them for Superbike

racing. Ducati has not announced any limited production numbers

for the revised 2005 model 999R, so we assume demand is now high

enough for the $30,000 racer that it will now be included on the

regular production line at the Bologna factory.

The

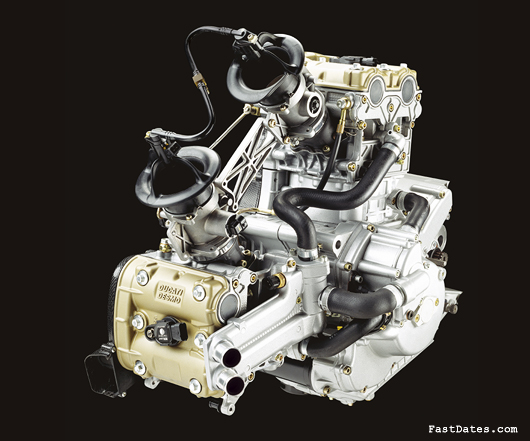

Engine

The basic dimensions of the Testastretta engine used on the new

999R remain the same as those of the previous version. The cylinder

bore is thus still 104 mm and the stroke stays at 58.8 mm, for

a total displacement of 999 cc. However, the maximum power and

torque have been greatly increased. Compared to the previous model's

102 kW (139 hp) at 10000 rpm, the new engine produces 110 kW (150

hp) at 9750 rpm. The torque itself has been increased from 108

Nm (11 kgm) at 8000 rpm, to 116.7 Nm (11.9 kgm) at 8000 rpm.

In order to fully understand what these figures mean for the new

999R, it is instructive to take a look at the variation in MEP

(Mean Effective Pressure). This value is an important parameter

in rating the engine, and measures the work the engine is capable

of doing throughout a complete cycle (i.e. through all four phases).

The Testastretta engine of the 999R ë04 has a MEP at maximum

torque of 13.6 bar. The new model, on the other hand, exceeds

14 bar, a limit which no series production Ducati engine has ever

reached before. At maximum power, the MEP value for the 999R model

year 2004 Testastretta engine is 12.3 bar, while on the MY ë05,

at the same power output, the value increases to 13.5 bar. It

is clear that in the two cases under consideration, the volumetric

and thermodynamic performance of the new engine (in other words,

its capacity to take in and burn the fuel/air mixture) are significantly

improved, thanks to the substantial technical upgrades to the

cylinder assemblies. In this context, it is worth noting that

the air flow rate in the intake ducts (permeability) has been

increased by 22.8%, while the exhaust duct flow rate has increased

by 5.8%. The overall optimisation of the engine is confirmed by

the fact that the improved maximum power value is now achieved

at an engine speed which is lower by 250 rpm than the corresponding

speed of the Testastretta engine mounted on the previous 999R

model. The engine speed limiter is set to 11000 rpm.

New

Cylinder Assemblies

In order to improve performance, the cylinder heads and pistons

have been completely redesigned and should really be regarded

as completely new components, designed specifically for racing.

The pistons are forged and constructed from an aluminium alloy

with high mechanical specifications to ensure outstanding geometrical

stability during the wide thermal excursions to which they are

subject. The variation of the geometrical specification, as well

as the new shape of the combustion cavity in the head, has resulted

in a compression ratio of 12.45 +/- 0.5 :1 (slightly greater than

that of the previous R version of the Testastretta engine, which

was rated at 12.3:1).

The valve

seats are deeper due to the increased valve lifts. The heads have

undergone a radical fluid-dynamics redesign. In order to make

it possible to use larger diameter valves, their centre distances

have been increased which means that the routing and dimensions

of the intake and exhaust ducts have also had to be modified.

Still in comparison to the previous 999R Testastretta, the squish

surfaces have been increased to improve the turbulent flow in

the combustion chamber, resulting in significantly increased combustion

efficiency. To summarise, the improvements to the new 999R engineís

cylinders have greatly increased the engine's ability to "breathe"

as well as its combustion output. The result of these modifications

is evident from the significant improvements in overall performance

of the road version, which means with absolutely standard exhaust

system, silencer and intake system.

The engine

also meets established emissions standards. It should be noted

that metal gaskets are not used between the head and cylinder

of each assembly, but rather special seal rings (called Wills

seals) around the perimeter of the combustion chamber. The large

cylinder bore makes this necessary if a perfect seal is to be

achieved. The overall redesign of the cylinder head has also made

it necessary to respecify the cooling ducts. The valve covers

are now in magnesium for lower weight.

Timing

Belts

To limit the temperature of the timing belts and not only to keep

down the overall weight of the vehicle, Ducati's competition bikes

have never been fitted with protective timing belt covers. However

these units are necessary to protect the belts when the bike runs

onto the gravel at the side of the track, and this year the Ducati

R&D department has installed timing belt covers with dynamic

cooling on the 999R, as already done on the 749R. The horizontal

cylinder timing belt cover has an intake with a small sponge filter

which attaches to the front fairing. The air is taken in at this

point, circulates in the timing belt housing and exits via a NACA

opening in the top of the vertical cylinder timing system cover.The

engine speed and phase timing wheel

A new element is the timing wheel on the timing drive shaft gear

which, along with an magnetic induction sensor, generates the

signal used by the ECU to detect the engine speed and operational

phase. The timing gear teeth are not used, as on previous Testastretta

engines, but instead the system uses a timing wheel with bumps

machined onto the outer circumference of the gear face itself.

This results in a cleaner electrical signal from the induction

sensor.

Engine Casings and Low Sump

The

engine casings are sand-cast, to highlight the exclusivity of

the product. The dimensions of the units are no different from

those used on the previous 999R Testastretta engine. The studbolts

which mount the cylinder assemblies are located in such a way

as to make it possible to mount such large bore cylinders (104

mm). The lubrication circuit retains the "low sump",

a fundamental feature of race engines, as this allows the oil

pump to always draw the lubricant in all vehicle positions (e.g.

bike cranked over, under harsh acceleration or with the front

wheel in the air).

Crankshaft

The

components in the engine casing of the Testastretta mounted on

the new model 999R have not undergone significant modification

compared to those used in the previous version, with the exception

of the crankshaft. This component now has a new configuration.

It is almost completely machined, to optimise its form. It has

thus been possible to obtain a weight reduction while maintaining

a perfectly balanced crank layout. The lubrication ducts inside

the crank pin are also completely new: they no longer run horizontally,

but diagonally while directly communicating with the duct along

the two main journals. In this way it has been possible to reduce

(from three to one) the number of plugs required to close off

the surface borings necessary for machining the ducts themselves.

The conrod manufactured by Pankl is in titanium to reduce the

weight of the crank linkages.

Valves

The Testastretta engine of the new 999R uses titanium valves,

both on the intake and exhaust. The weight saving is considerable,

especially if we consider the strong accelerations imposed by

the high engine speed. The valve diameter is 42 mm on the intake

with valve lift of 13 mm, and 34 mm on the exhaust with lift of

11.5 mm. On the previous 999R's engine the intake valve diameter

was 40 mm with 11.71 mm lift and the exhaust valve diameter was

33 mm with 10.5 mm lift. The use of titanium has obliged Ducati

to use special valves seats and guides. The timing diagram has

not been substantially changed relative to the previous 999R engine,

although the cams are of a completely new shape. The intake valves

now open by 21∞ before the TDC, compared with a previous

value of 16∞, and close 53∞ after BDC relative to

the previous 60∞. The exhaust valves open at 60∞ before

BDC as before, while they close 20∞ after TDC compared to

a previous value of 18∞. The inclination of the intake and

exhaust valves on the new 999R is no different from that of the

old version, at 12∞ and 13∞ respectively off the cylinder-head

axis. In line with Superbike race engines, the retaining system

on the closing register valve stem has been changed. This register

is acted on by the desmodromic timing rocker to close the valve,

and its thickness determines the play between its surface and

the fork-shaped ends of the rocker itself, with which it contacts.

This play must be adjusted with great precision, since it greatly

affects the mechanical stress on the timing components, as the

valve returns to its seat. It also affects the timing diagram,

which must be close to the nominal diagram. The closing register

retainer system normally used on series Ducati engines exploits

the action of two half-rings seated in a cavity machined near

to the upper end of the valve stem. These two half-rings engage

the register. However, this system has evident limits on a race

engine which is often run at its top engine speed. In these conditions

the half-rings are severely stressed and tend to deform plastically

(they are crushed) and hence do not guarantee a constant play

between the register and the rocker. For this reason the Testastretta

engine of the 999R uses two titanium half-cones which encircle

the valve stem. They have a circular section bump on their inner

surface which engages with the groove machined near to the end

of the valve stem itself. This groove is however not as deep as

that used for the half-ring system. Furthermore, the two half-cones,

when the steel closing register is pressing against them, grip

the valve stem under friction, thus considerably reducing the

stresses around the groove. This enables the valve stems of the

new 999R to be not 7 mm (as used on the other Testastretta engines)

but 6 mm, resulting in a further weight saving. It is also worth

noting that the half-cones, since they perfectly couple with the

register, are not subject to deformation even though they are

highly stressed. This means that the valve closure play remains

constant for a longer time when the engine is running. As already

indicated, the valve centre distance has been increased over that

on the previous 999R's Testastretta engine. It has thus been possible

to use parts with a larger diameter head. Each valve has been

moved outwards (orthogonally to the ducts) by 0.75 mm, for an

overall increase in stem centre distance of 1.5 mm (the new centre

distances are 43 mm between the two exhaust valves and 46.8 mm

between the two intake valves). The valve seats also have a higher

position relative to those of the previous engine. It follows

that they protrude more into the head combustion cavity, which

has been completely redesigned along with the larger squish surfaces.

The volume of the cavity is thus less than that in the heads of

the previous model engine. As already indicated, the consequent

increase in the compression ratio has been limited by reducing

the height of the piston head.

The

Intake and Exhaust Systems

Nothing has changed in the new 999R's intake and exhaust systems

compared to the previous version. There is a single, large volume

silencer, and the manifolds have no intersection points. In particular,

the difference in length between the front cylinder manifold compared

to the shorter rear cylinder manifold has been compensated for

with a number of differing cross-sections (varying from 45 to

55 mm for the front unit, constant at 45 mm for the rear unit),

so as to ensure identical fluid-dynamic behaviour of both exhaust

systems. Furthermore, the rear cylinder manifold penetrates into

the silencer. The Testastretta engine used on the road version

of the Ducati 999R is equipped with catalytic converters. Each

cylinder assembly has a dedicated three-way catalytic converter.

The one on the front cylinder is fitted about halfway along its

exhaust manifold, while the rear cylinder unit is integrated into

the initial section of the silencer. The airbox has a large volume

(12.5 dm3 ) and is not closed off by the lower surface of the

fuel tank. The ducts which lead the intake air from the dynamic

scoops on the front fairing to the airbox are equipped with a

Helmholtz resonator to reduce intake noise without penalising

engine performance. The RH duct is integral to the coolant tank.

Engine

Type Twin-cylinder L-configuration,

Desmodromic timing,

4 valves per cylinder,

liquid cooled

Engine bore 104 mm

Stroke 58.8 mm

Total displacement 999 cm3

Maximum power 150 HP @ 9750 rpm

Maximum torque 11.9 kgm @ 8000 rpm

Compression ratio 12.45:1

Intake valve diameter 42 mm

Intake valve lift 13 mm

Exhaust valve diameter 34 mm

Exhaust valve lift 11.5 mm

Intake/exhaust valve material titanium

Valve angle (inclusive) 25∞

Timing diagram (with 1 mm valve play)

Intake:

Opening before TDC 21∞

Closing after BDC 53∞

Exhaust:

Opening before BDC 60∞

Closing after TDC 20∞

Conrod centre distance 124 mm

Conrod material titanium

Primary transmission ratio 32/59

Gear ratios First 15/37; Second 17/30; Third 20/28; Fourth 22/26;

Fifth 23/24; Sixth 24/23

Final transmission ratio 15/36

Clutch type Multi-disk, dry sump

Oil pump Gear type

Lubrication circuit capacity 3.8 l

Generator 480 Watt

Electronic ignition/injection ECU IAW 5M2

Ignition stick coil, in sparkplug seat

Injectors one per cylinder, IWPR2, 12-jet

Theft alarm Immobilizer integral to engine ECU

Click for

a bigger view.

Frame

and Two-Member Swingarm

There have been no substantial modifications to the frame used

on the previous 999R, which is still of the trestle type, constructed

in high strength steel tubing. The suspended engine is a bearing

component and contributes to the torsional rigidity of the assembly.

The cross-member supporting the starter motor on the series production

bike is removable to enable use of a larger capacity fuel tank,

as provided by the championship regulations. The footplates can

be moved to two different positions. A great deal of attention

has been paid to weight distribution and the location of each

single component, which plays a fundamental role in transferring

the loads experienced during dynamic riding (braking, acceleration,

curves). Indeed, the individual components must be as close together

as possible to contain the arms on which the masses act and as

a result the momentum generated, so as to ensure highly responsive

handling of the motorcycle. This is yet another reason why Ducati

has followed the principle of maximum integration in designing

the bike, with the aim of achieving a high density of components

in a reduced volume. The swing arm is identical to that of the

motorcycle which will be raced in the Superbike championships.

The fulcrum support is an aluminium casting, while each arm is

composed of two sheet profiles pressed and welded together to

achieve a box cross-section. The left hand member also includes

a lower reinforcing member. The wheel shaft is supported by two

forged units welded to the ends of the arms. These components

are equipped with a failure screw specified to a specific breaking

strain which thus ensures that the wheelbase cannot be lengthened

under stress. The wheelbase is the same as that of the 999 and

the distance between the wheel centre and swing arm fulcrum is

490 mm +/ñ 12.5 mm (the variability is enabled by the chain

tensioning slot). If the failure screw is removed and the rear

wheel is set to its furthest back position, the swing arm centre

distance is 512.5 mm. In this case the motorcycle's wheelbase

is such as to counteract sudden variations in position during

dynamic braking and acceleration (thus reducing rear wheel grip

failure under braking and counteracting front wheel lift under

acceleration while guaranteeing sufficient drive).

Forged

Aluminium Alloy Wheels

The rear and front wheel rims are made of forged aluminium, a

technology which enables weight reduction while maintaining resistance

to mechanical stress. Compared to castings, it is possible to

use thinner sections since the material is distributed evenly

throughout the component. The lower weight of the rims not only

reduces the suspended masses (which significantly improves suspension

performance), but also greatly reduces the gyroscope effect and

improves the handling of the bike at high speeds (the bike is

more agile when entering curves). Forging is done with a hydraulic

press using special dies with a load of thousands of tons. The

material thus becomes plastic while maintaining its original molecular

structure and hence guaranteeing the mechanical properties of

the finished part, even with greatly reduced sections. Casting,

on the other hand, requires the metal to be liquid, which alters

its molecular structure, and the material is poured into a mould

for cooling. There is thus no certainty that the material perfectly

fills all the mould cavities. To ensure that the mechanical strength

of the part is adequate, castings must therefore be thicker and

heavier than forged parts.

The

Front Forks and New Rear Shock Absorber

The front forks and the new rear shock absorberThe callipers of

the front brakes are radially mounted to special mounts on a new

÷hlins fork, the legs of which are surfaced in TiN for

improved sliding. The two legs have modified, smaller diameter

springs and the spring guide is now in plastic rather than metal.

This reduces the formation of detritus which tends to pollute

the oil. The lower section of the cartridge rod is fitted with

a counterspring, which counteracts the main spring at maximum

extension during violent acceleration. The usual cam system allows

the steering head angle to be adjusted and thus also the trail

(91 ñ 97 mm). The rear shock absorber has been improved

by making rebound damper adjustment completely independent (with

a one-way valve), so that the rebound damper no longer acts on

the compression damper.

New

Front Fairing

The headlamp mount and the new mirror mounts are now in magnesium

alloy. The fairings with scoops, front fairing between the two

side fairings, the front mudguard, chain guard, silencer heat

shield and windshield fairing are all in carbon fibre. The tail

section, on the other hand, is in techno-polymer. The forms of

the fairings are identical to those on the 999R, while the windshield

fairing has changed and now lacks the upper flow guides while

featuring a plexiglass windshield with a new shape. Overall, apart

from improved aerodynamics, the new system provides better rider

protection at high speed (when crouched over the fuel tank) and

better visibility of the instrumentation (the black rubber surround

of the plexiglass windshield does not block the rider's view of

the instrument panel warning lights).

Electronics

More sophisticated engine ECU

The new 999R's engine ECU uses the same sensors and actuators

as the preceding version. However, the ECU itself has been changed

to the IAW 5M2 unit, again produced by Magneti Marelli, and is

now capable of handling a larger number of inputs and outputs,

to allow for future expansion of the regulation strategies. The

injectors (IWPR2), again from Magneti Marelli, are identical to

those used on the race bike and have a higher flow rate for the

same opening time. They have 12 atomisation jets and tighter,

more constant flow tolerance. The form of the spray and the very

small droplet size make an essential contribution to the outstanding

performance of the engine. The spark plugs are surface discharge

units, Champion RG59V. They do not have the traditional protruding

ground electrode, so that the spark no longer follows a fixed

route, but is rather generated around the central electrode in

the most favourable direction. This greatly reduces the probability

of misfires and hence failure of mixture combustion in the chamber.

The coils are of the stick type and are therefore located in the

spark plug seat on each head. The electrical connection is no

longer directly mounted to the body to avoid potential damage

due to vibration.

The

CAN bus ñ a more streamlined electrical system

The use of a CAN (Controller Area Network) network with two main

nodes: instrument panel and engine ECU (Magneti Marelli IAW 5M2),

has greatly simplified the electrical system, with a significant

weight reduction. To limit the number of cable bundles the designers

have eliminated duplications in the number of sensors on the motorcycle.

Their signals must therefore be shared by the various on-board

processors. This can only be done by sending the sensor's signal

to the closest controller, which is then charged with sending

it on to the network so that it can be used by the processors

which need it. The CAN bus network is composed of only two cables

carrying trains of digital signals, each of which carries precise,

perfectly decodable information. The nodes of the network (the

instrument panel and the engine ECU), have special hardware which

enables them to recognise which signal trains concern them and

must therefore be processed by their processors. This technology

enables a considerable simplification of the electrical system,

which in some sections is composed of no more than the double

CAN bus cable.

Chassis

Specifications

Frame steel tubing,

trestle-type

Trail 91 - 97 mm

Steering head angle 23°30’ – 24°30’

Wheelbase 1420 mm

Front suspension stroke 120 mm

Front fork leg diameter 43 mm

Rear suspension stroke 71 mm

Rear wheel travel 128 mm

Front rims and tyres rim MT 3.50x17” tyre 120/70 17

Rear rims and tyres rim MT 5.50x17” tyre 190/50 17

Minimum ground clearance 125 mm Seat height 780 mm

Rider footplate height adjustable to 387 mm and 410 mm

Seat height

780 mm

Maximum width 730 mm

Handlebar width 671 mm

Maximum length 2095 mm

Steering angle 28° 30’ right/left

Dry weight (without fluids and battery) 181 kg

Front brake disks (diameter) 320 mm

Rear brake disk (diameter) 240 mm

Radial four piston front brake callipers 34 mm (piston diameter)

Two piston rear brake calliper 34 mm (piston diameter)

Front brake master cylinder piston 18 mm (piston diameter

Rear brake master cylinder piston 11 mm (piston diameter)

Go

to: Ducati 999R05 Information

Page 1 • Test Page 2

• Test Page 3 •

999F05

Return

to Ducati

Index • New

Bike Index • Pit

Lane News |